Is whining bearings or gears.......I'm thinking more like gears?

Solder, hmmm. Compress 1mm solder down to perhaps .1mm?

The cover plate can flex .05mm reasonably easy by hand pressure. My question re solder is, how much does the solder distort the cover when it gets screwed down? If you give the cover a whack to help squash the solder, all bets are off.

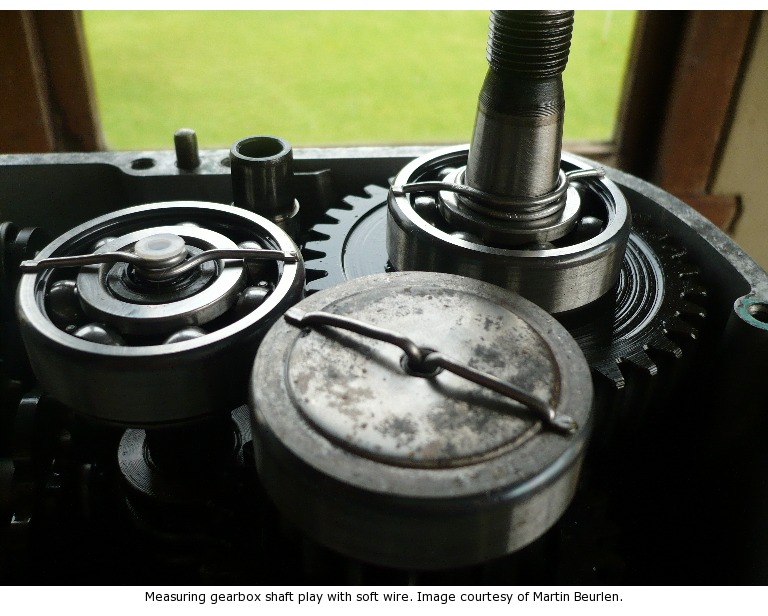

The clearances called for are minute. There are a few things that can throw a taken measurement out the window.

Plastigauge will not withstand the heat necessary to install the cover plate. There is another option mentioned by Cycle Works, some sort of setting putty. But it requires the whole tranny to be heated to quite a high temp. Me no likey.

The front input shaft bearing is easy to replace. Well, the outer race is. The input shaft has to be dismantled (maybe not a big deal) to remove the inner race.

I replaced the outer with new, and left the inner original. Should be ok I think.

Re bearings being manufactured as matched inner and outer, I don't believe such is the case in mass produced stuff.

Example, new f truck disc rotors come with new outers only.....

If your cover plate is slightly warped, measuring pocket depth

at the pocket will give a false reading.

Measure across the whole plate for real world accuracy.

Joerg's motorcycle pages offer good info.

http://jhau.maliwi.de/mot/gearbox.html

There are a few precautions but so far for me, it has been fairly easy.

Have a crack Garnet.