Re: Gear ratio confusion

Posted: Thu Oct 04, 2018 8:35 pm

melville wrote: ↑Thu Oct 04, 2018 5:23 pm I think there's a reduction gear on the input that is not part of the gear ratio calculation for the oilhead trans but that is part of the calculation for the airhead trans.

From this:

http://largiader.com/tech/oiltrans/sixspeed.html

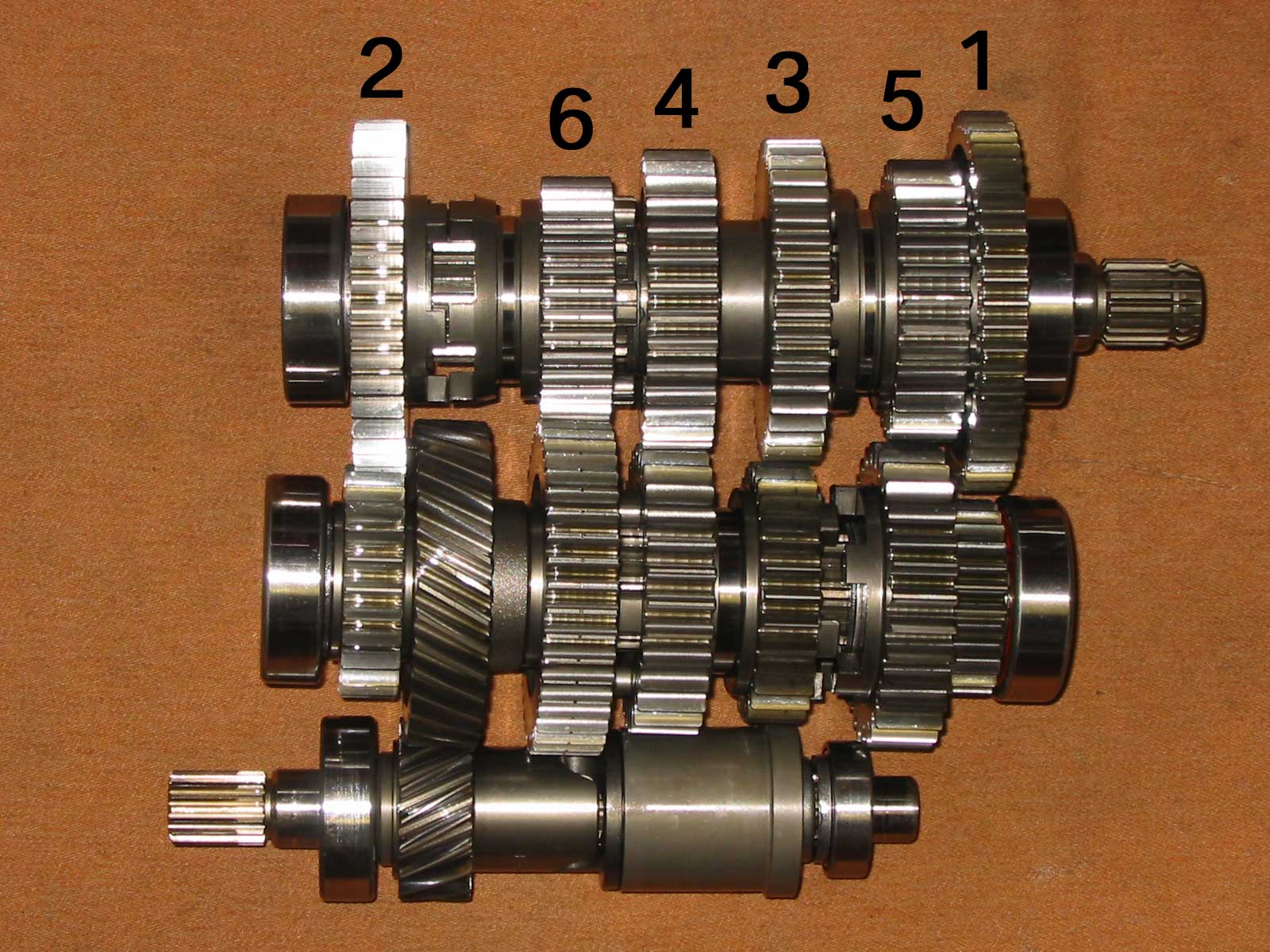

See the input shaft at the bottom:

That looks like at least a 2:1 input ratio. So the Airhead ratios measure the difference between crank rpm and output rpm, while the published Oilhead ratios measure the difference between the two shafts with all the gears on them.

Thanks for that info. I was aware that both transmission used 3 shafts, and there is some reduction with the extra shaft.

But was not aware that BMW didn't calculate gear ratios on the Oilhead trans without including that reduction.

Doesn't make sense to me. Since all those gears and shafts are in the trans, they should be providing the ratios as input shaft vs output shaft. On bikes that have primary drives, I understand that being a separate value.

Thanks for the extra info I didn't have.