Page 3 of 5

Re: My left nut....

Posted: Sat May 26, 2012 9:00 am

by Deleted User 287

Yeah dwire, I am with you - I would want as long a lever as practical to reduce the amount of force needed.

Maybe buy one of those tools from BMW that come in the tool kit and cut it in half and weld the end you need on the end of a very long piece of steel tubing.

That 2nd person? I would use them to make sure I don't flip the bike up against the garage wall.

Maybe two extra people for a fastener this stubborn.

Re: My left nut....

Posted: Sat May 26, 2012 9:19 am

by dougie

justoneoftheguys wrote:

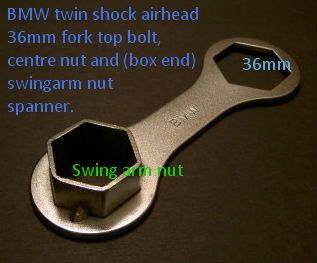

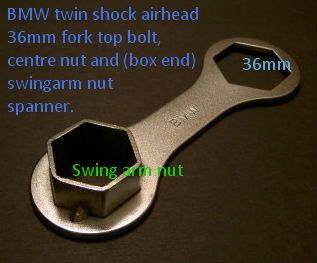

I have one of these.

Doubt that it is beefy enough for this kind of fight.

Re: My left nut....

Posted: Sat May 26, 2012 10:06 am

by SteveD

Ratchet: this sort of thing with the ground down 36mm socket..

I have one of those BMW tools on the way. I have used one in the past, which did the job. it should be somewhere over Uzbekistan about now! I intend to use the second person to stabilise the bike whilst I try to loosen it. I find that the bike wants to "walk" a little ccw whilst I'm trying to provide the force. I doubt that helps.

I have one of those BMW tools on the way. I have used one in the past, which did the job. it should be somewhere over Uzbekistan about now! I intend to use the second person to stabilise the bike whilst I try to loosen it. I find that the bike wants to "walk" a little ccw whilst I'm trying to provide the force. I doubt that helps.

I have removed these before, it's just that this one is being recalcitrant!

Re: My left nut....

Posted: Sat May 26, 2012 3:04 pm

by dwire

Boy Steve, don't know what to tell you. I have done well with removing thsee, even at astronomical torques - they had to be even beyond the spec which seems darn high when you are putting it back together and realize it is time for your tenth "do-over" because the forks that you spent all that time making perfect are now no longer perfect and will be putting everything in a bind.

I am assuming that is a stock photo - you are NOT using an extension, correct? That would make this impossible as particularly with something this tight, when you introduce an extension the side-loading goes through the roof and for something like this guarantees failure. I have maybe 2 or 3 simple, non-ratcheting, fold over drive (the drive end will fold over so you get more attempts at lining the hex's up for that maximum mechanical advantage I spoke of before...) I keep 1/4" 3/8" and 1/2" drive handy in the big tool chest. My socket was actually run in a lathe - surely you could get away without, but I got to chose how much more I took off. After perusing different possible uses for the socket, I took off a great deal more than just the champfer; this gets the drive (where your torque angle begins) as close to that fastener as possible - and I knew this was going to be a tool ONLY ever used for those top bolts.

Have you had an opportunity to look elsewhere online for methods on this? I already mentioned where I know there is an excellent source that just works and frankly upon reassembly which is SO MUCH HARDER since you have fork alignment to worry about, I found everything mentioned there to bare out one way or another. I'd bet there are a number of other sites I now can't recall that used to be up, that have procedures that may differ slightly, but I am afraid on this deal I'd have to say there are not many ways to skin this cat...

Re: My left nut....

Posted: Sat May 26, 2012 6:39 pm

by Deleted User 287

Time for a set of K-bike forks?

Re: My left nut....

Posted: Sat May 26, 2012 8:38 pm

by SteveD

Importantly, I'm not in a hurry. Winter has set in here, and as it's the weekend, parking at work is a little easier, and free.

I'm on nights later this coming week, and I don't ride to work on nights. That's the only time I regularly take the car.

It's proven difficult so far, but I'm not so worried about it just yet.

I'll get it off, not too worried about it. I've had a go with tools I have available, but now to move on to the next method when it gets here.

I have replacement parts already, so they'll be nice and unburred when they go back in.

Re: My left nut....

Posted: Fri Jun 01, 2012 4:25 am

by SteveD

This arrived today.

I placed it over the nasty nut, gave it two medium strength whacks with a mallet...off came the nut. Too easy.

I musta loosened it a tad with my other attempts!

Re: My left nut....

Posted: Fri Jun 01, 2012 4:57 am

by ME 109

NUTS!!

Re: My left nut....

Posted: Fri Jun 01, 2012 5:31 am

by Deleted User 287

That sure is a pretty picture!

congratulations!

Re: My left nut....

Posted: Fri Jun 01, 2012 8:27 am

by dwire

You did order the "B" version right? I think from what you were indicating, only the "B" (for buggered up hex) type wrench will fit properly.

Yeah, I'm sure that wrench may be helpful, but how you brace the wrench and fork assembly means more than the wrench does in most cases. That could be a bit tough to use too. What, does one use a piece of flat stock and catch the very side of the flat part of the wrench, or use a more conventional bracing method that invariably will end up against the hexagonal OD of the other end of the wrench? It will be interesting to hear how you get it off. Second person holding everything down with all the force in the world and a whack with a dead blow hammer? dunno - you are way out of my league on this one. BUT PLEASE DO CHIME IN AND LET US KNOW YOUR TECHNIQUE when you succeed as surely this will happen to someone else and surely has before; we just have been unable to search for it well enough...