Page 3 of 4

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 7:52 am

by StephenB

SteveD wrote:Interesting read. Anyone remember what GSPD recommended? He was in the tighter corner wasn't he?

From an email, GSPD sent to me in 2008:

GSPD wrote:I have always set mine at around 0.06 (0.0023") mm and 0.12mm (0.0047") and I've never had

a clearance related issue in over 370,000km.

I basically check mine whenever one side begins to sound a bit noisier than the other while riding.

He had this different way of adjusting the valve clearance (based on the thread pitch) to eliminate all possible play:

GSPD wrote:

Starting at 0 clearance between set screw and pushrod end, back off the set screw 45 degrees on the exhausts, this

gives you about 0.12mm, backing off 22.5 degrees on the intakes, this gives you about 0.06mm

Or, if you are skeptical about running them 'too tight',

back off slightly less than1 flat (1/6 turn= 0.1666 mm) on the exhausts

and slightly more than 1/2 a flat (1/12 turn=0.08333) on the intakes

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 11:49 am

by Garnet

StephenB wrote:SteveD wrote:Interesting read. Anyone remember what GSPD recommended? He was in the tighter corner wasn't he?

From an email, GSPD sent to me in 2008:

GSPD wrote:I have always set mine at around 0.06 (0.0023") mm and 0.12mm (0.0047") and I've never had

a clearance related issue in over 370,000km.

I basically check mine whenever one side begins to sound a bit noisier than the other while riding.

He had this different way of adjusting the valve clearance (based on the thread pitch) to eliminate all possible play:

GSPD wrote:

Starting at 0 clearance between set screw and pushrod end, back off the set screw 45 degrees on the exhausts, this

gives you about 0.12mm, backing off 22.5 degrees on the intakes, this gives you about 0.06mm

Or, if you are skeptical about running them 'too tight',

back off slightly less than1 flat (1/6 turn= 0.1666 mm) on the exhausts

and slightly more than 1/2 a flat (1/12 turn=0.08333) on the intakes

I have been following GSPD's method for the last couple of years now.

Remember when my tag line was "Loud Valves save Lives"?

On the clearance side another reason to have

some clearance is to get oil between the tips of the rockers and the valves and pushrods as well a between the lifter and cam lobe.

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 12:43 pm

by barryh

Sounds like GSPD was running tight clearances without problems.

OK point taken that it's how long the exhaust valve is open that counts where heat is concerned so the % change is bigger. But we are still talking about a very mild cam here. The exhaust valve on a 308 cam is open 52 deg longer than an R60/5 cam so any increase from closing up clearances on an R60/5 is minor by comparison.

I was suggesting to Stephen that he close up his clearances which will open his valves a little longer so that will usually increase power.

It's me that goes the other way. I open up the clearances because most of my riding is either commuting or trundling down country lanes at 50mph or less. The small amount of tractability I gain helps in this sort of riding.

I'm acutely aware that people may think I'm making too much of all this so I've consistently said the effects are small but real. Many years back before the days of hydraulic tappets I noticed that an old pushrod Ford I had was a bit more tractable with wider clearances. I just applied the same thinking to an airhead. I'm not entirely ploughing a lone furrow here. If you were to google "Valve clearance effects on power" there are a 2 or 3 relevant references out there. Just to add confusion there is also a contrary effect claimed by one tuner who reckons opening up clearances can actually increase power due to the fact that how fast a valve opens is just as important as when it opens. We had better not go there.

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 1:17 pm

by Ken in Oklahoma

barryh wrote:. . . people may think I'm making too much of all this . . .

I wouldn't be one of them. It could be said that's pretty much what we do here at Boxerworks.

Ken

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 1:50 pm

by StephenB

barryh wrote:I was suggesting to Stephen that he close up his clearances which will open his valves a little longer so that will usually increase power.

Yes, so you did. But please remember that me questioning came form the issue of pinking, not the increase of power.

Wikipedia wrote:

Knocking (also called knock, detonation, spark knock, pinging or pinking) in spark-ignition internal combustion engines occurs when combustion of the air/fuel mixture in the cylinder starts off correctly in response to ignition by the spark plug, but one or more pockets of air/fuel mixture explode outside the envelope of the normal combustion front.

The fuel-air charge is meant to be ignited by the spark plug only, and at a precise time in the piston's stroke cycle. Knock occurs when the peak of the combustion process no longer occurs at the optimum moment for the four-stroke cycle. The shock wave creates the characteristic metallic "pinging" sound, and cylinder pressure increases dramatically. Effects of engine knocking range from inconsequential to completely destructive

So, how exactly is extending valve opening/closure times reducing the pinking?

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 2:44 pm

by Major Softie

StephenB wrote:

So, how exactly is extending valve opening/closure times reducing the pinking?

Oh fine, keep us on task (good luck with that, by the way: quite the . . . task).

The tightest clearances possible can yield slightly more overlap, which will slightly reduce effective compression at lower rpm's, which could reduce pinging (that overlap also slightly increases power at higher rpm). The amounts we are talking about here are so small that I doubt it would be noticeable unless the original pinging was

very minimal.

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 4:06 pm

by barryh

StephenB wrote: So, how exactly is extending valve opening/closure times reducing the pinking?

We all know reducing the compression ratio should reduce pinging.

We think of compression ratio as nominally the swept cylinder volume divided by the cylinder head volume but in reality it isn't. Compression can't begin until the inlet valve closes and it doesn't close until after bottom dead centre so dynamic compression is reduced from the simple static ratio.

A R60/5 closes it's inlet valve at 40 deg ABDC

A 308 cam closes it's inlet valve at 44 deg ABDC

Closing up your inlet valve clearance will move the valve closing point from 40 Deg maybe half way towards 44 therefore it will make a

small reduction in dynamic compression which can only help with pinging.

Now to degrade the thread and completely destroy my credibility.

If you have a minor pinging and want to eliminate it I have a snake oil sounding solution that actually works. Add a small amount of 2 stroke oil to your fuel in the ratio of 1:640. There are a lot of claims on the web that dosing petrol or diesel fuel with 2 stroke oil in this ratio acts as an upper cylinder lubricant and improves fuel consumption. I'm not claiming that or at least I don't have enough evidence to claim that. I do know that my 9.8:1 compression engine will ping a little on 95 Ron fuel and if I add two stroke oil in this ratio it stops. Others have tried this and found the same. Why exactly it works I don't know but it must have the effect of slowing down combustion a touch. Having a trace of oil in the fuel can't do any harm in terms of corrosion prevention in the tank or lubrication of the carb. And who ever heard of a two stroke with a rusty exhaust. Only other effect is a very slight coloring of the plugs. The oil must be marine TCW3 rated which means it's ashless and leaves no deposits when it burns.

Re: Cam choice r60/5

Posted: Sat Mar 02, 2013 10:07 pm

by StephenB

See, it's coming together nicely and I learned something new today.

So, 1:640, eh! I feel some weight on my leg, something is pulling there ....

But then, 1:640 equates to approx 30ml 2-stroke oil per 20l of gas ... that's a similar ratio for injector cleaner used on a car.

Now, just hold on a second: I just heard that dynamic compression reduction is the deal against pinking or any compression reduction for that matter. A trace of oil in the gas would lead to better sealing and thus to higher compression rather than lower ... so I can't follow that logic with your hi-comp engine.

Re: Cam choice r60/5

Posted: Sun Mar 03, 2013 12:19 am

by Garnet

StephenB wrote:See, it's coming together nicely and I learned something new today.

So, 1:640, eh! I feel some weight on my leg, something is pulling there ....

A trace of oil in the gas would lead to better sealing and thus to higher compression rather than lower ... so I can't follow that logic with your hi-comp engine.

A tiny bit of oil in the combustion chamber slows combustion, reducing pinking......... and power.

By closing the intake valve a bit later you bring down the efective compression at lower RPMs (2500-4000) where the pinking is at it's worst, with a slight loss of power. Above 3500-4000 the speed of the incoming fuel charge fills the cylinder and raises the compression, but at now at an RPM that better matches ignition, resulting in complete combustion, more power and no detonation.

I have no idea why BMW did not deal with this problem during the 7 year life of the 247 R60 engine.

Re: Cam choice r60/5

Posted: Sun Mar 03, 2013 4:58 am

by chasbmw

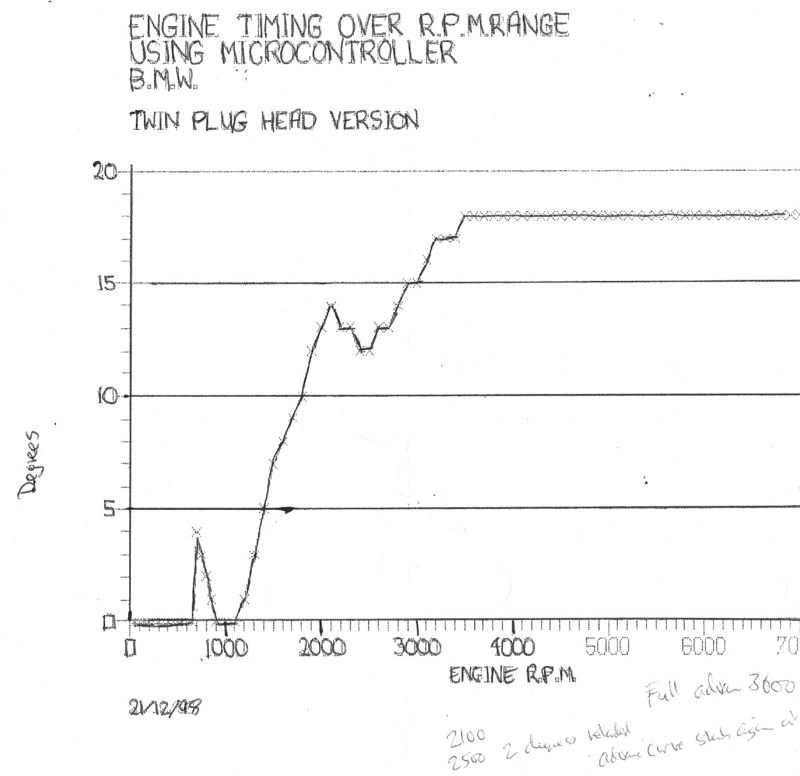

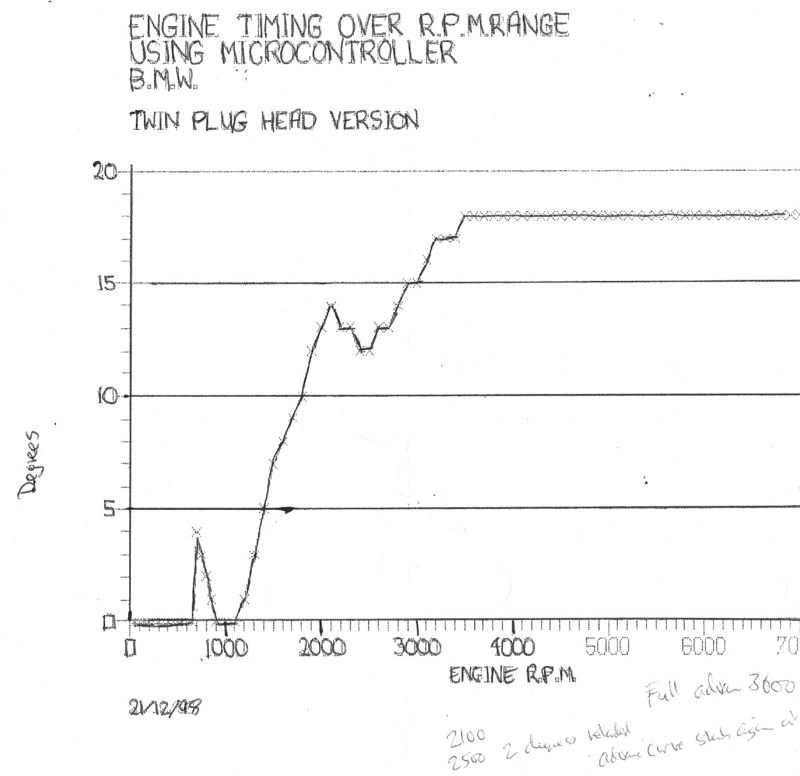

The Boyer microdigital ignition curve was designed for R60s, in that it retards the ignition a tad between 2500 and 3000 revs, to reduce pinging.