Re: Woo Hoo! A Big Project!

Posted: Tue Mar 31, 2015 10:25 pm

The goal here is not rearsets specifically, but 'samesets.' I use the passenger pegs when I want to be folded into a pretzel away from yoga. The other goal is to use as many OG parts as possible and to make it look just like BMW would have done, only nicer.

I obtained an extra right peg from PITApan. Here's how it looked after I got the powdercoat people to blast the plating off it and the original one from my bike:

They were both a bit bent from various incidents. I got the cheater pipe out and bent them out just a bit, then it was time to clean up the forge part lines:

A little grinding to get a flat spot on the peg and a lot of grinding on my pivot extension to get a weldable bevel later, it was time to jig it up for tack welds:

Muriel helped with that--so many moving parts!

The shift lever and the shifter stub on the trans needed to be tapped to M6 to use the pivot ball:

And the connecting bit needed to be shortened and threads cut:

I left it a bit long--it's easy enough to shorten it a mm or two at a time.

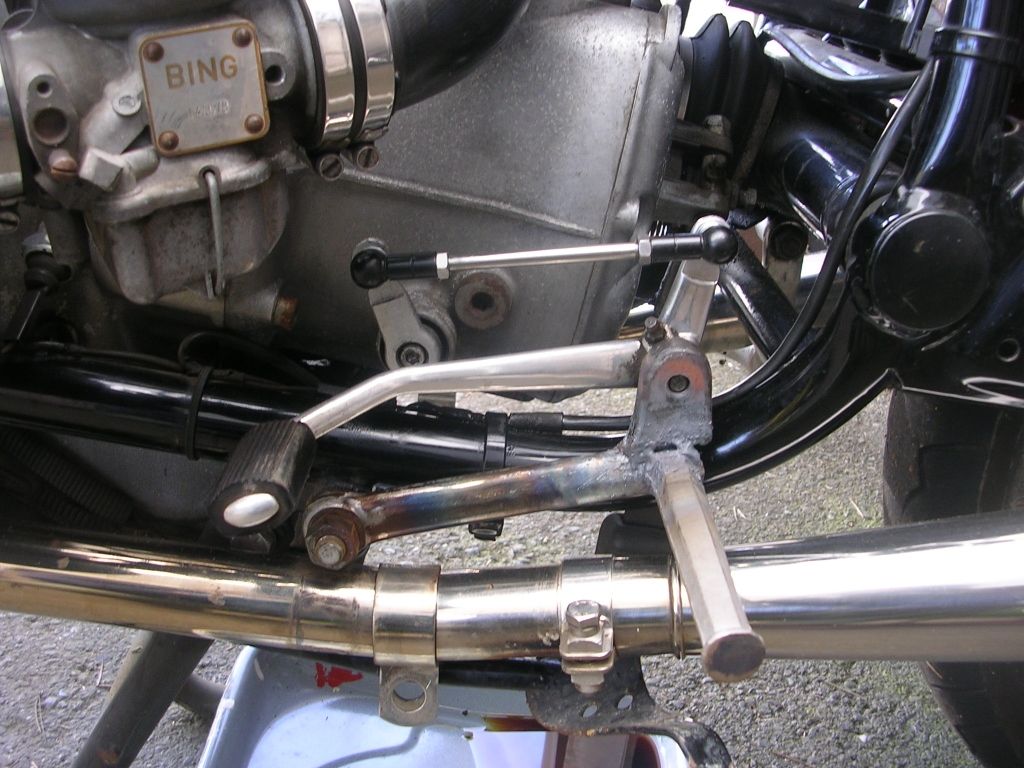

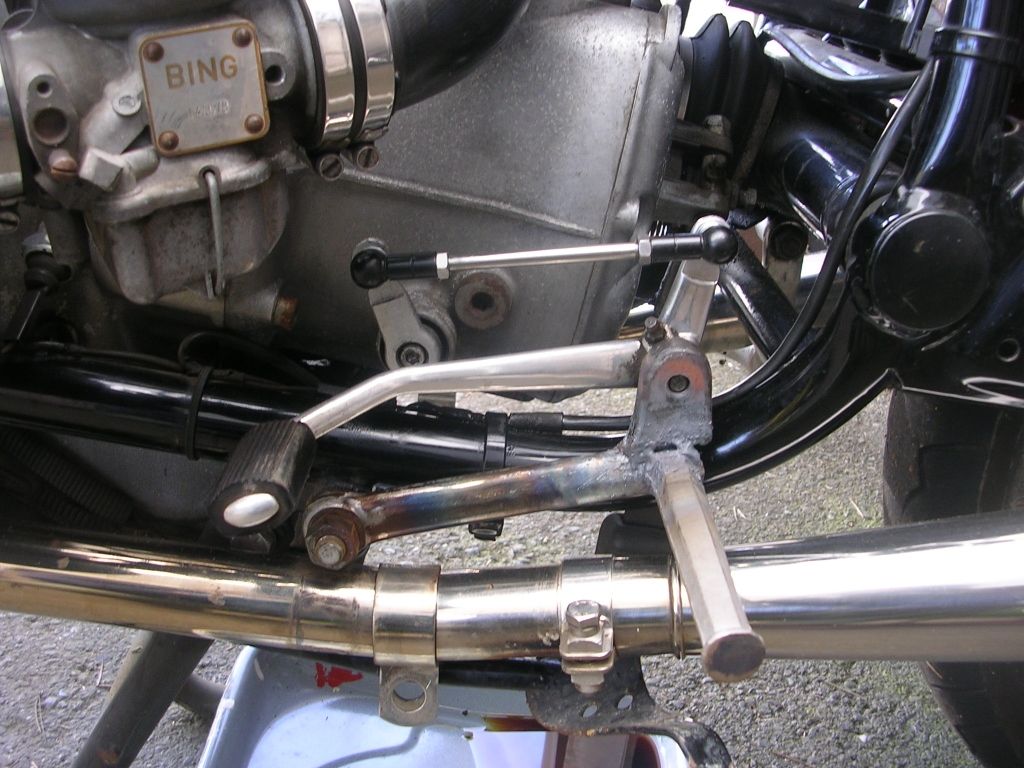

And here it is, mocked up:

It seems to work!

Please do not let your eyes linger on the world's ugliest tack welds. That will be dealt with once I get a bigger tip for the torch. A #3 barely made the metal sweat, let alone puddle.

Coming up: better welds, PC for the pegs, and my tires are in!

I obtained an extra right peg from PITApan. Here's how it looked after I got the powdercoat people to blast the plating off it and the original one from my bike:

They were both a bit bent from various incidents. I got the cheater pipe out and bent them out just a bit, then it was time to clean up the forge part lines:

A little grinding to get a flat spot on the peg and a lot of grinding on my pivot extension to get a weldable bevel later, it was time to jig it up for tack welds:

Muriel helped with that--so many moving parts!

The shift lever and the shifter stub on the trans needed to be tapped to M6 to use the pivot ball:

And the connecting bit needed to be shortened and threads cut:

I left it a bit long--it's easy enough to shorten it a mm or two at a time.

And here it is, mocked up:

It seems to work!

Please do not let your eyes linger on the world's ugliest tack welds. That will be dealt with once I get a bigger tip for the torch. A #3 barely made the metal sweat, let alone puddle.

Coming up: better welds, PC for the pegs, and my tires are in!