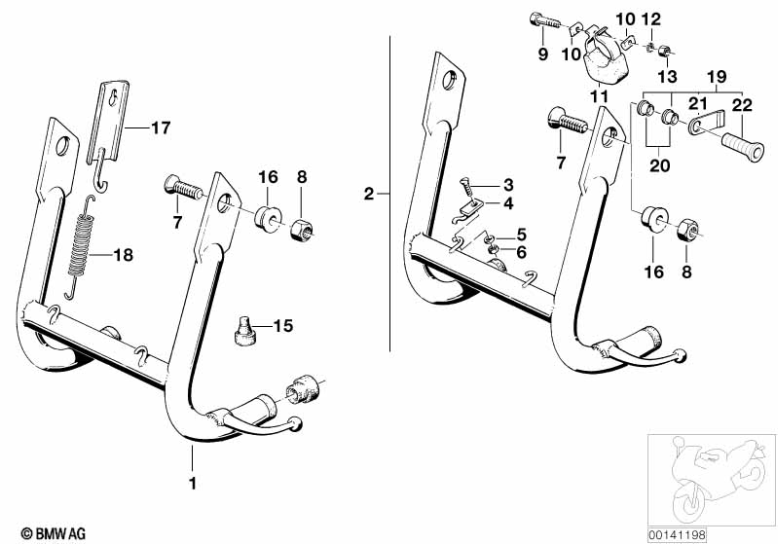

R100RS centre stand repair.

Posted: Sat Feb 15, 2025 12:58 am

I'm hoping to get mine modified this weekend.

The plan:

1. reduce height by 13mm.

2. lay a weld across the top, a little wider than the current pressed together bits.

3. take the stand home and continue to mod it to best fit.

Question. When the stand tubes are cut and a bit removed, what is the ID of the tubing? I'll need to get something appropriate diameter to slot in there to strengthen the job. Or I could cut it and measure myself

Cheers

Well ovaled. They look better in the picture. I had one of them shimmed already. BUT...what might be the best approach to correcting the oval shape which extends the hole upwards. Add weld and shape accordingly? Enlarge the hole, weld in a spacer of the same diameter of the original hole?

The spacers were the long version. A little worn, but still serviceable. I'll likely replace them. The nuts and bolts were fine.

The ground contact points had a weld reinforcement maybe 10-12 years back. Held up well, but probably added 2-3mm to the height. One of the improvements is to reduce the height a little. 285mm from the bottom to the pointy bit at the top.

The contact points at the top were worn, sloping inwards. I need to have a good look at the frame contact points too!

I'm awaiting confirmation from the welder to get the welds done tomorrow. Then I'll bring it home and sculpt it to fit and function on the bike. These three pics are from Jeff, ME 109. I'll be looking to do something similar.

I doubt my skills will be as elegant as Jeffs, but I'm hoping the stand ends up just as effective.

The plan:

1. reduce height by 13mm.

2. lay a weld across the top, a little wider than the current pressed together bits.

3. take the stand home and continue to mod it to best fit.

Question. When the stand tubes are cut and a bit removed, what is the ID of the tubing? I'll need to get something appropriate diameter to slot in there to strengthen the job. Or I could cut it and measure myself

Cheers

Well ovaled. They look better in the picture. I had one of them shimmed already. BUT...what might be the best approach to correcting the oval shape which extends the hole upwards. Add weld and shape accordingly? Enlarge the hole, weld in a spacer of the same diameter of the original hole?

The spacers were the long version. A little worn, but still serviceable. I'll likely replace them. The nuts and bolts were fine.

The ground contact points had a weld reinforcement maybe 10-12 years back. Held up well, but probably added 2-3mm to the height. One of the improvements is to reduce the height a little. 285mm from the bottom to the pointy bit at the top.

The contact points at the top were worn, sloping inwards. I need to have a good look at the frame contact points too!

I'm awaiting confirmation from the welder to get the welds done tomorrow. Then I'll bring it home and sculpt it to fit and function on the bike. These three pics are from Jeff, ME 109. I'll be looking to do something similar.

I doubt my skills will be as elegant as Jeffs, but I'm hoping the stand ends up just as effective.