ME 109 has inspired me.

Posted: Fri Dec 07, 2012 12:35 am

I have a /7 5-speed that needs rebearinging. I had thought I'd ship it off to GSPD one day when I had some extra cash, but after following Jeff's adventures, I'm seriously considering dong it myself. (Insert laugh track.)

It is one of the last airhead frontiers for me, always considered a no go zone for mortals. But now the internet has shown that an ordinaryJeff Joe can do the job with just a few special tools.

I have a couple of questions:

It seems that the front input shaft bearing is not always changed.

Does it stand up better than the ball bearings, or is it that it's just too freakin expensive?

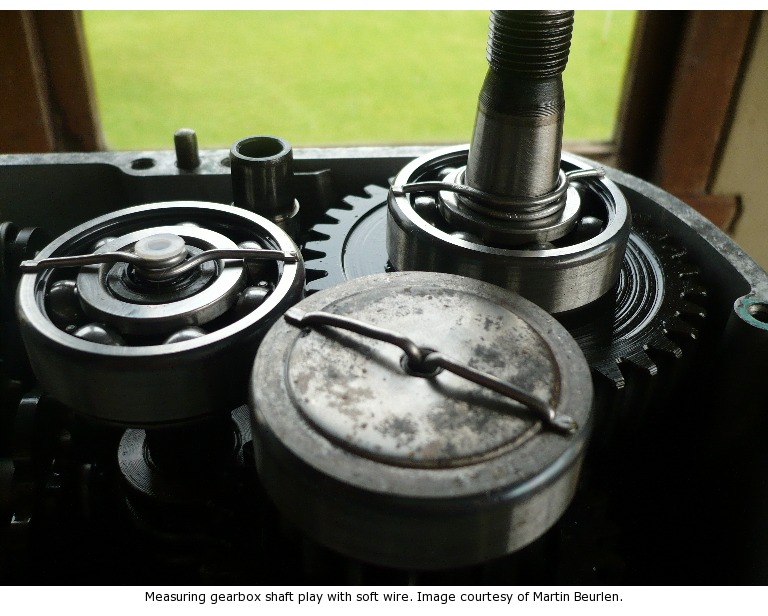

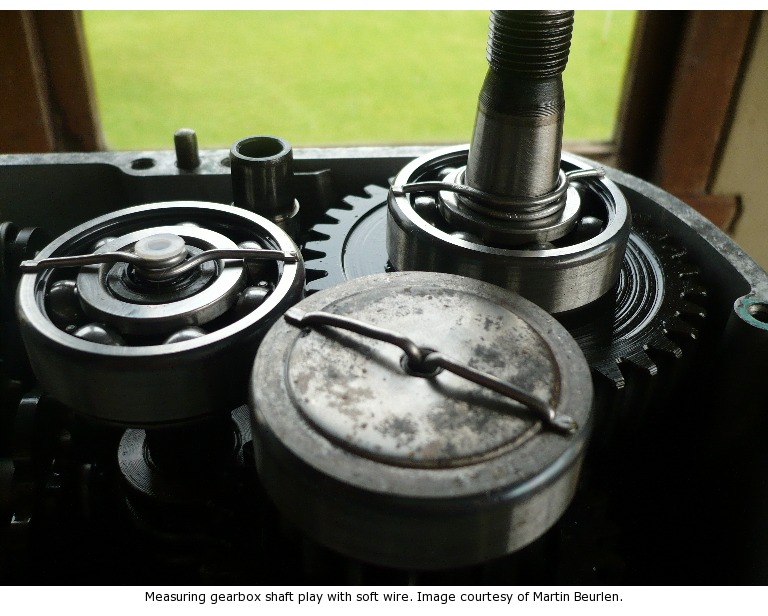

Rather than useing a shimming plate to measure bearing clearance,

has anyone used plasti-gauge or solder?

It requires installing and removeing the cover a couple of extra times, but seems like a simpler way to make the measurement.

The box shifts well so I don't think there is any big isues other than a lot of whinning in the lower gears. What else should I expect to do while I'm in there?

It is one of the last airhead frontiers for me, always considered a no go zone for mortals. But now the internet has shown that an ordinary

I have a couple of questions:

It seems that the front input shaft bearing is not always changed.

Does it stand up better than the ball bearings, or is it that it's just too freakin expensive?

Rather than useing a shimming plate to measure bearing clearance,

has anyone used plasti-gauge or solder?

It requires installing and removeing the cover a couple of extra times, but seems like a simpler way to make the measurement.

The box shifts well so I don't think there is any big isues other than a lot of whinning in the lower gears. What else should I expect to do while I'm in there?