...that 36 mm top nut at the top of the forks is a bugger to get out.

I bought a 36mm socket from Autobarn which fits beautifully and it got the right one off easy enough.

The left one is causing some trouble.

I've given it a few good "impacts", I've applied heat via a heat gun around the top of the fork leg, I've sprayed it with penetrant....

My next step will be to grind down the socket so that it has a full advantage. The height of the nut head is "not much".

Any other ideas before I proceed? How much heat f'instance?

My left nut....

My left nut....

Cheers, Steve

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Re: My left nut....

Good to grind the socket down Steve, but do it precisely or little advantage will be gained.

As much heat as you can get frOm the heat gun won't be too much (IMO)

A rattle gun set on low would be the duck's nuts.

And then of course, buy new nuts.

They are another example of airhead airheadedness.

As much heat as you can get frOm the heat gun won't be too much (IMO)

A rattle gun set on low would be the duck's nuts.

And then of course, buy new nuts.

They are another example of airhead airheadedness.

Lord of the Bings

Re: My left nut....

Hi Steve,

I wouldn't think heat or penetrating oil will make a big difference, given that

1) its unlikely to be seized as it caps off an oil filled tube

2) you can't go to town with the heat (like heating it with an oxy-torch til it glows sort of heat)

Its just a big nut (bolt actually on my model) done up tight.

You have to get enough purchase, so grinding that taper off the nut is vital. If a socket won't do it, a flat fitted 6 side ring spanner is best, (is that in the OEM tool kit?), so that you can smack it. The offset of a socket and bar stuffs you for using impact.

cheers

mal

I wouldn't think heat or penetrating oil will make a big difference, given that

1) its unlikely to be seized as it caps off an oil filled tube

2) you can't go to town with the heat (like heating it with an oxy-torch til it glows sort of heat)

Its just a big nut (bolt actually on my model) done up tight.

You have to get enough purchase, so grinding that taper off the nut is vital. If a socket won't do it, a flat fitted 6 side ring spanner is best, (is that in the OEM tool kit?), so that you can smack it. The offset of a socket and bar stuffs you for using impact.

cheers

mal

Re: My left nut....

Thanks for the replies...

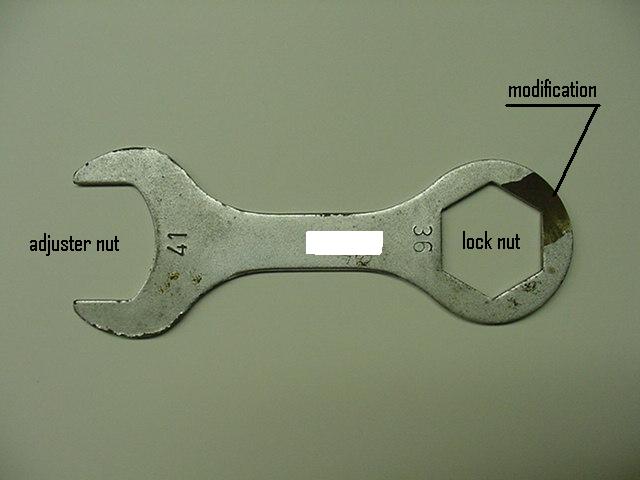

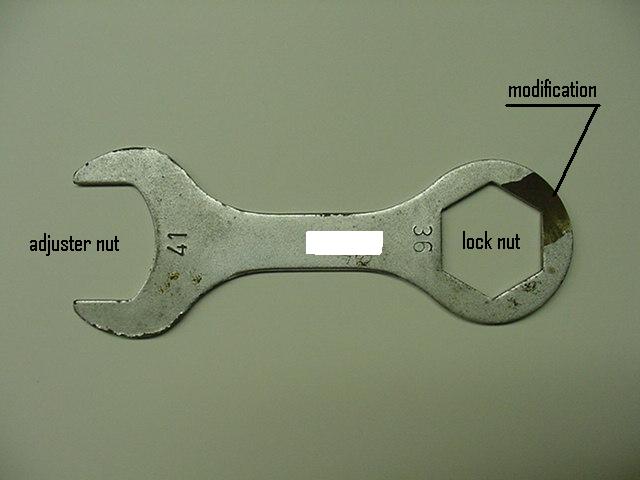

This is what I need I expect, but instead of 36mm, the one I have measures 42mm. What's that for?

The more I try, the more damage to the nut...two points are now rounded. I need to stop, grind the socket and try tomorrow after applying as much heat as possible. All I have for that purpose is the heat gun.

Maybe the boys at BM Motorcycles will lend me the correct tool? Can't hurt to ask.edit: in fact, come to think of it, I think they have a 36mm round ended spanner already ground that I might've used years ago. I could go buy one myself I guess.

This is what I need I expect, but instead of 36mm, the one I have measures 42mm. What's that for?

The more I try, the more damage to the nut...two points are now rounded. I need to stop, grind the socket and try tomorrow after applying as much heat as possible. All I have for that purpose is the heat gun.

Maybe the boys at BM Motorcycles will lend me the correct tool? Can't hurt to ask.edit: in fact, come to think of it, I think they have a 36mm round ended spanner already ground that I might've used years ago. I could go buy one myself I guess.

Cheers, Steve

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

-

Kurt in S.A.

- Posts: 1709

- Joined: Tue Aug 03, 2010 12:08 pm

Re: My left nut....

42mm might be for another bike's fork nuts?

I used the 36mm socket with the leading edge cut back...it's the tool to have...make sure it's 6-point not 12-point. I used my impact wrench and was able to lean down on the wrench to keep the socket for walking off, damaging the corners. I believe Duane mentions grinding paste...this helps with the bite.

Kurt in S.A.

I used the 36mm socket with the leading edge cut back...it's the tool to have...make sure it's 6-point not 12-point. I used my impact wrench and was able to lean down on the wrench to keep the socket for walking off, damaging the corners. I believe Duane mentions grinding paste...this helps with the bite.

Kurt in S.A.

Re: My left nut....

Thanks Kurt...that's what I have. Too late to grind tonight...and the paste is a great idea too!Kurt in S.A. wrote:42mm might be for another bike's fork nuts?

I used the 36mm socket with the leading edge cut back...it's the tool to have...make sure it's 6-point not 12-point. I used my impact wrench and was able to lean down on the wrench to keep the socket for walking off, damaging the corners. I believe Duane mentions grinding paste...this helps with the bite.

Kurt in S.A.

Cheers, Steve

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Re: My left nut....

When I ground my socket, I used a socket driver mounted in a drill so I could spin the socket as I ground it.

Made quick work of it and left a nice even finish.

Used the same to make the swing arm modified socket

Made quick work of it and left a nice even finish.

Used the same to make the swing arm modified socket

'74 - R90/6

-

Deleted User 72

Re: My left nut....

Since the "nut" is actually a bolt, you are swimming upstream using heat, as you are expanding the bolt into the tube - making it tighter. Dry ice (frozen CO2) in the hollow of the bolt might help.SteveD wrote: I need to stop, grind the socket and try tomorrow after applying as much heat as possible. All I have for that purpose is the heat gun.

Re: My left bolt....

I was applying the heat circumferentially around the top of the fork, under the bolt. Nut made for a catchier title thoughNative /5 wrote:Since the "nut" is actually a bolt, you are swimming upstream using heat, as you are expanding the bolt into the tube - making it tighter. Dry ice (frozen CO2) in the hollow of the bolt might help.SteveD wrote: I need to stop, grind the socket and try tomorrow after applying as much heat as possible. All I have for that purpose is the heat gun.

Cheers, Steve

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Victoria, S.E.Oz.

1982 R100RSR100RS supergallery. https://boxerboy81.smugmug.com/R100RS

2006 K1200R.

1994 R1100GS.

Re: My left bolt....

Got my attention.SteveD wrote: Nut made for a catchier title though

I've spent most of my money on women, motorcycles, and beer.

The rest of it I just wasted.

The rest of it I just wasted.