I also have some "mold-a-gauge" from Cycle works, and will try that.

Here's the question- I saw here-

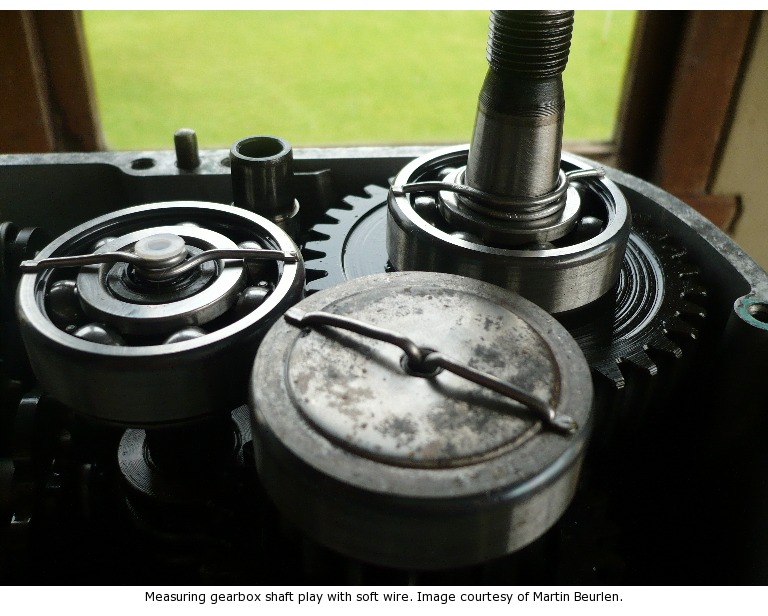

- a way to use soft solder as a measurement gauge for shims. Anybody done this? Suggestions? Seems like it would work great, and take the guesswork out.

- a way to use soft solder as a measurement gauge for shims. Anybody done this? Suggestions? Seems like it would work great, and take the guesswork out.Don