Page 3 of 3

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Wed Mar 30, 2022 9:52 pm

by Airbear

kmisterk wrote: ↑Wed Mar 30, 2022 12:03 am

Wow. I'm now wanting to do a conversion to the mo.unit on my r100. DO you have the STL file for the headlamp casing?

Also, I may have missed it, but did you link to the cluster you used? This is such a cool idea, and I'd *love* to get this going on my bike.

Thanks kmisterk. Yes, I'll be able to send you the STL files for the bucket, supports and other bits. Send me a PM and include your email address. My stuff is printed with ABS+ but there may be other options, particularly if you have access to a resin printer. ABS filament printing has its challenges and I had to do a lot of tweaking to get sufficient strength. The temp controlled enclosure, at 60C, made the difference in preventing warping during the print.

My first attempt at a printed bucket and ears went well for a couple of years but a trip in 2019 on the same bloody road - the Barry Way in southern NSW - when it was dry and very corrugated, saw the fronts of both ears break and the headlight dangling by its umbilical cord.

- Brun.jpg (292.42 KiB) Viewed 1336 times

- brokenear.jpg (134.94 KiB) Viewed 1336 times

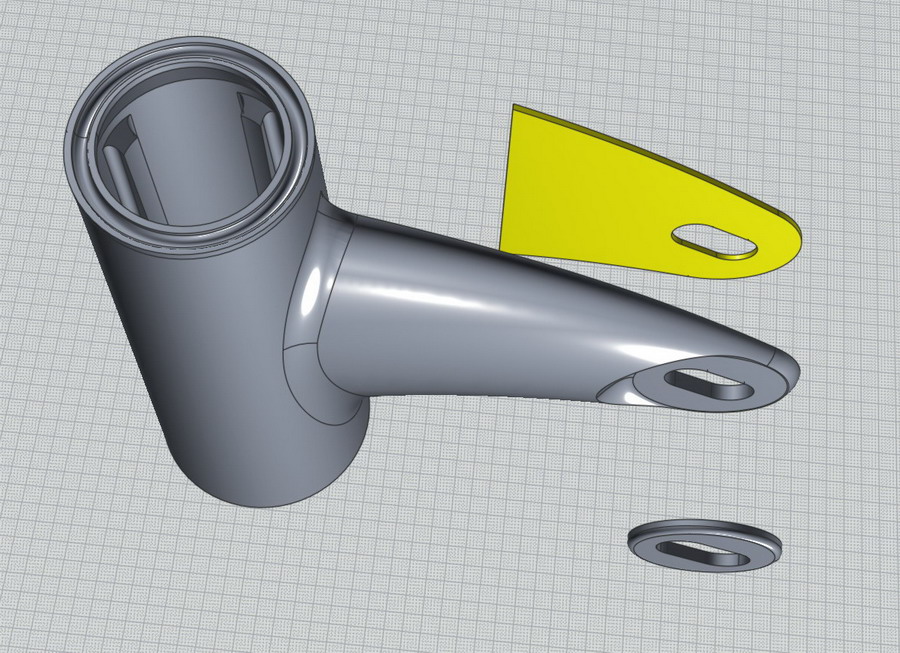

I redesigned the ears to include a groove for an o-ring at the top and made an aluminium reinforcing plate that is glued on with West System epoxy.

- ear.jpg (185.23 KiB) Viewed 1336 times

If by 'cluster' you mean the warning lights, those bits were also printed. More later ...

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Wed Mar 30, 2022 10:42 pm

by melville

Ooooohhhhh!

I'm curious about the BMW wheel in the fancy fork. Was that difficult?

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Wed Mar 30, 2022 11:56 pm

by gspd

Airbear - Again I admire and commend your excellent workmanship, but what exactly initially prompted you to ditch your original (overbuilt?) steel bucket and ears to remanufacture them in plastic? Were they rotted out or crash-damaged? I imagine all your new electrics could easily have fit in the old shell, especially with the void provided by that thin speedhut speedo.

Plastic is definitely corrosion resistant and lighter, and your re-design has a better speedo tilt, but are there any other advantages? Any regrets?

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Thu Mar 31, 2022 1:37 am

by Airbear

MotoD wrote: ↑Wed Mar 30, 2022 9:45 pm

I do agree in most cases. If it ain’t broke, don’t fix it. I do love the new technical upgrades as I’ve done on this R100. I even did a remote master cylinder for the new dual Brembos. I’ll get a build thread up soon. Again, great work to you!

2F44F83E-FD4F-41D2-8E08-9DBD75A04F53.jpeg

3F4BC3F6-1402-4880-B543-FD5D447B4A87.jpeg

Oh, that is very nice indeed. I hope you've been taking a lot of photos along the way.

I'm looking forward to the next re-wire so I can hide most of the cables and do a s bunch of things differently.

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Thu Mar 31, 2022 2:03 am

by Airbear

gspd wrote: ↑Wed Mar 30, 2022 11:56 pm

Airbear - Again I admire and commend your excellent workmanship, but what exactly initially prompted you to ditch your original (overbuilt?) steel bucket and ears to remanufacture them in plastic? Were they rotted out or crash-damaged? I imagine all your new electrics could easily have fit in the old shell, especially with the void provided by that thin speedhut speedo.

Plastic is definitely corrosion resistant and lighter, and your re-design has a better speedo tilt, but are there any other advantages? Any regrets?

On page 1 of this thread I wrote:

"Some background information: Brunhilde came into my care 19 years ago as a basically stock example [edit: of a /6] with 153k kms on the clock. A few months later we had a midnight collision with a black cow, resulting in significant damage to the bike, the cow and myself. The forks were bent, the original small tank had a knee-shaped dent, the handlebar was bent to the point where the front wheel could not point forward, and the front mudguard, headlight and instruments were totally trashed. The VIN plate on the steering head was even scraped off by the headlight, and I had to go back to the accident scene to find it. So the bike was no longer a stock example, but hey, what an opportunity to start modifying! The cow died the following day and I had my left shoulder rebuilt with aftermarket parts.

Since that time she’s worn a variety of headlights and instruments, always heading towards the Slash Five aesthetic, since I’m a Slash Five tragic who could only find a Slash Six at the time I had sufficient dollars to consider buying a BMW airhead. Thanks for reading."

So I was on the lookout for a /5 headlight bucket and ears, now very thin on the ground. A request on the ADVRider forum led to getting the loan of a (barely bashed) bucket from the US, and an Australian mate sent me a set of ears. I measured and modelled these, made adjustments to suit the cheap bits I wanted to fit and started printing. There were many fails but I'm now close to something that pleases me.

Or more briefly, I wanted something that I couldn't afford so I had to make it.

Re: Mo-Unit Blue, re-wiring and 3D printed bits, etc

Posted: Thu Mar 31, 2022 9:53 am

by gspd

Airbear wrote: ↑Thu Mar 31, 2022 2:03 am

Or more briefly, I wanted something that I couldn't afford so I had to make it.

I'm having a hard time adjusting my brain to how expensive and/or unavailable a lot of airhead parts have become.

The days of finding good deals on cheap parts in the junk room of your local BMW dealer or at jumbles and swap meets are gone.

Heck, in the (what seems like) not so distant past I've bought complete /5 parts bikes for less than a simple used /5 headlight shell now brings.

I guess that's why us old people are always saying: "If I knew then what I know now, I'd be filthy rich."

Keep up the good work!